Eager.one supports the future of offshore floating installation

We are glad to be sharing our knowledge in OffshoreWIND.Biz. We have recently published our first article on the future of offshore floating installation. The article is written together with Seaqualize. Enjoy reading!

Offshore heavy lifting: Why use power, if you have balance?

The offshore wind industry is growing significantly and is moving towards larger wind turbine sizes and deeper water. This causes a rising demand for alternative installation methods besides the well-known and most commonly used jack-up vessels. One of the alternatives is installation by means of floating crane vessels. Next to multiple advantages, floating installation of offshore wind farms can also be challenging and requires innovative solutions to de-risk the technology and reduce costs.

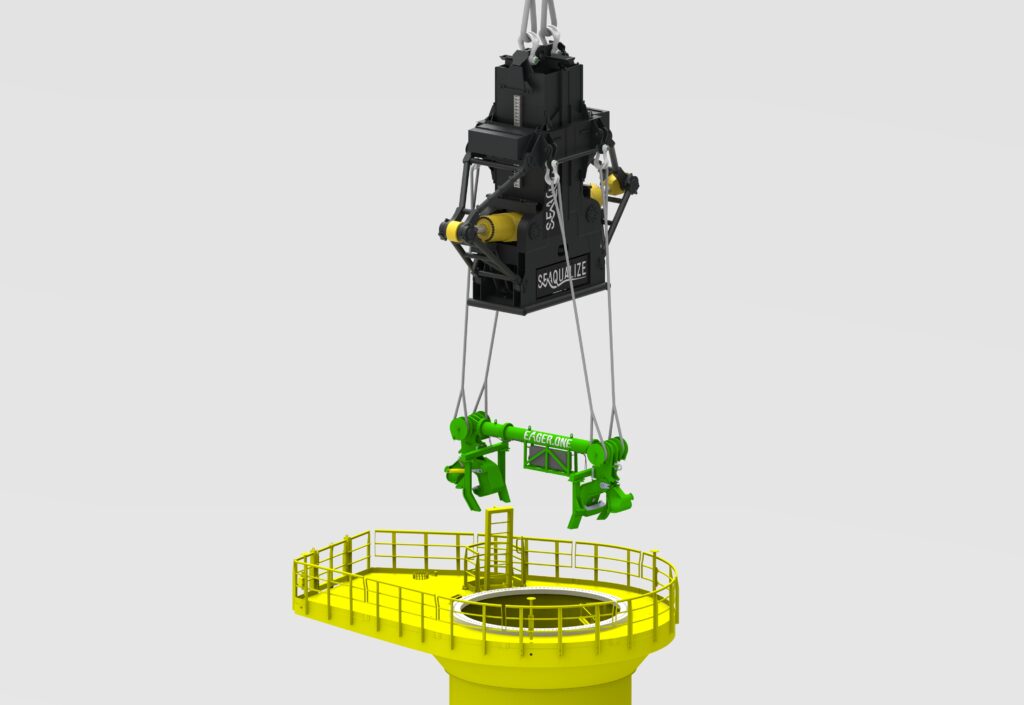

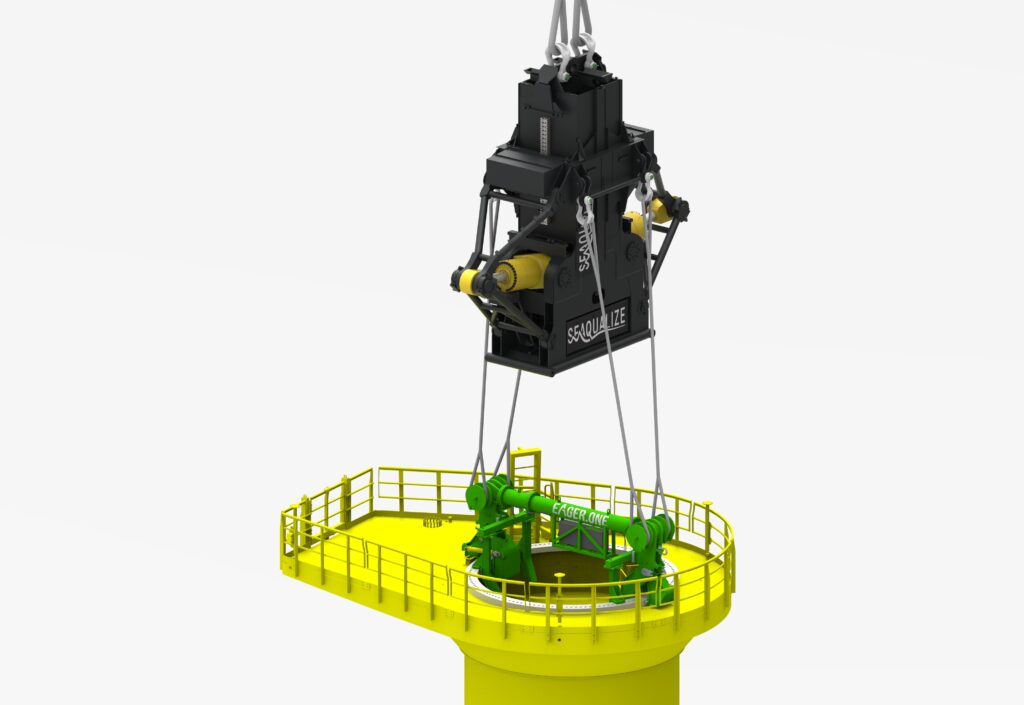

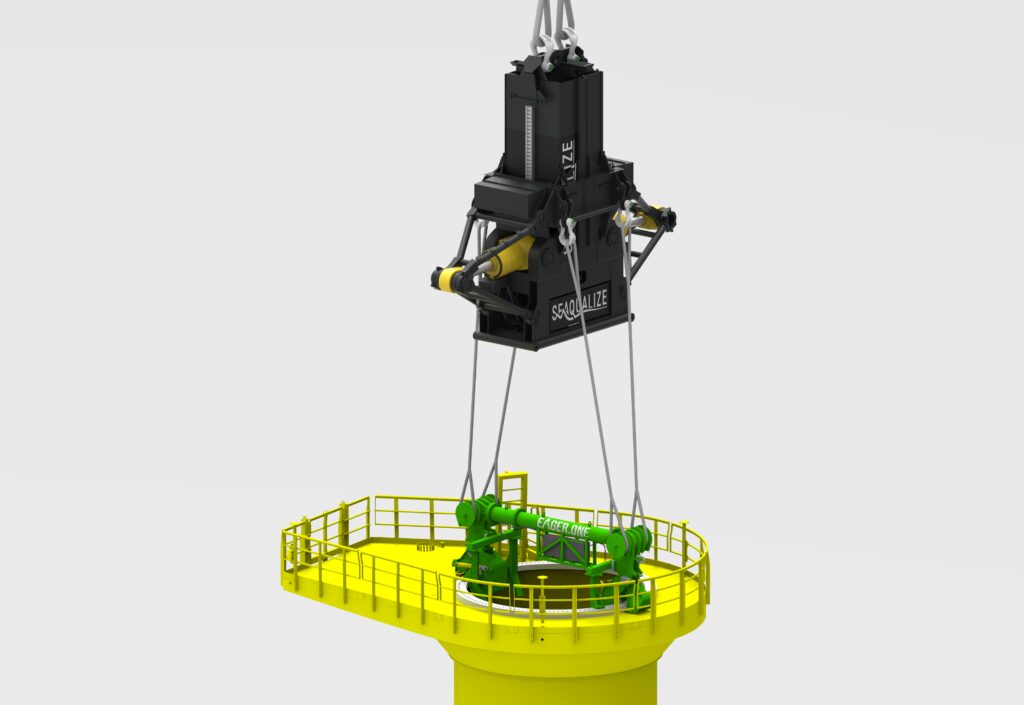

The Seaqualize Delta is one of the innovative tools that opens up the road to floating installation of offshore wind farms. Together with engineering partner Eager.one, Seaqualize has developed the first hook-based active heave compensation tool, for in-air heavy lifts: the Delta series.

Floating Installation

Until recently, jack-up vessels were the preferred option for offshore installation of wind turbines, as this sidesteps wave motions affecting operations. But there are three developments why the market is looking at an alternative: floating installation

- We are running out of ‘easy locations’ – Already installations are planned in increasingly deeper waters, or locations with jacking-unfriendly soil conditions.

- Wind turbine sizes are significantly increasing, which will exceed the capacity of the jack-up crane load, but not yet the capacity of heavy lift vessels.

- In a market that needs all cost reductions it can get, it can be beneficial to apply heavy lift vessels, that are already built, available and ready to go without new investment.

Installing wind turbines from floating vessels can be very complex and increase safety risks. We already mentioned the environmental influences that are affecting operations. With floating installation they become even more prominent as you continuously have to deal with movements that are difficult to compensate with standard equipment.

Still, the above advantages make clear that it can be very worthwhile to investigate the potential for your operations.

Compensation of heave

A very important challenge in floating installation is the compensation of heave (movements in the Z-direction). The market has historical experience with passive heave compensation (PHC) for shock absorption due to heave, but PHC is not equipped to slowly set down delicate equipment on a fixed landing target. That can only be done with active heave compensation (AHC). AHC cranes are available in the market, but performance is targeted on sub-sea, and they require a significant structural CAPEX investment.

The Seaqualize Delta series is the first hook-based active heave compensation tool, for in-air heavy lifts. Ranging from ~50 mT to eventually 2.000 mT and beyond, it opens up the road to floating installations of offshore wind turbine components or, complete turbines at once. The patented technology combines a very strong passive system, which renders the full load ‘weightless’ or balanced. A very small active system (~10%) ensures extreme power efficiency (600mT version is still battery powered), to precisely position the load, and does not allow for accidental lift-offs or shock loads. This dual system is called: balanced heave compensation (BHC).

During the development process of the Delta series, Seaqualize has contacted Eager.one to be the engineering partner. The cooperation between both parties has resulted in this state-of-the art in-air heave compensation tool that turns every standard heavy lift crane into a high-performance AHC crane, only when required for the job.

Advantages Balanced Heave Compensation

Floating vessels that are using balanced heave compensation tools offer the many advantages of floating installations: No more restrictions regarding water depth, earthquakes or bad soil and more operation time as soil surveys and time for jacking is eliminated.

Next to that, the workable hours are increased as it is no longer necessary to wait for improved weather conditions, compared to floating installation without proper heave compensation. This increases the installation season significantly. For example, the Seaqualize Delta can offer up to ~20-40% workability increase, especially in the demanding North-Sea.

A flexible system like the Seaqualize Delta can be operated by many different crane types. It can be used to install all offshore wind turbine components, from monopile to topsides, in combination with different types of lifting tools, that are also part of the Eager.one portfolio, like Transition Piece (TP) lifting tools and Anode Cage lifting tools and Secondary Steel installation tools that are required for TP-less monopile foundations.

Also, the varying weights of components is no longer an issue. The tool automatically adjusts its settings, or when the load differs >20% than the expected lift, settings can be fully adjusted on board, within just 15 minutes.

And last but not least, the usage of balanced heave compensation tools for lifting wind turbine components results in a significant safety increase for the people on board. Its constant variable tension ensures no snatch loads, accidental lift-offs and re-hits, creating a much safer working environment.

Up next for floating installations: TP-less monopiles and feeder barges

Floating installation of monopiles without transition pieces will be used more often. This requires more auxiliary equipment, like boat landings, to be installed. For the installation of these types of equipment, bespoke lifting tools, used with motion compensation, would be very suitable.

Eager.one has extensive experience in the design and supply of these types of tools as well. And in combination with the different types of balanced heave compensation systems, this is a perfect solution for the floating installation of all types of equipment in the near future. The more heavy lift Seaqualize Delta1000 and Delta2000 are coming up, for the installation of complete wind turbines. But also the Delta100 for the more lightweight equipment, like boat landings and anode cages.

New developments for other, innovative motion compensated installation or lifting tools are still accelerating. Two examples: Eager.one has recently designed one of the world’s largest motion compensated monopile grippers for the offshore wind industry. And lastly: the US wind market currently still requires feeder barge supply lifts. Instead of working with vessel based heave compensation, a hook-based balanced heave compensation tool offers increased workability at lower costs. Exciting times ahead in the world of floating installation!

This article was also published on OffshoreWind.biz

What we do

As an independent partner, we advise about, design and construct everything from concept study to project completed. Our in-house developed design software calculates everything concerning mobile cranes and bespoke heavy equipment, while our people offer the expertise and skills that secure your success.

GET YOUR PROJECT PREPARED

Consultancy / Design & Construction

Our 40 years of experience provides the basis of a successful start of your project: right from the FEED phase. Preparation is vital. Therefore our concept studies, method statements and mission equipment offer you all the support you need.

GET YOUR PROJECT EXECUTION SUPPORTED

Consultancy / Design & Construction

Our aim is to optimize your project team’s results. With our exclusive knowledge of lifting and transportation we eliminate and manage risks. This is how we reach our collective goal: Zero Accidents, Zero Incidents.

DESIGN OF LIFTING & TRANSPORT ASSETS

Engineering

We have built up a great deal of experience with the design of (mobile) cranes and bespoke heavy equipment such as piling machines and excavators. Our customer base includes the most prominent producers of cranes and heavy machinery worldwide.

We are eager to hear from you

Call +31 (0) 30 240 80 60 or use the contact form. We always respond within 24 hours.